Secondary Crusher In Cement Plant

.jpg)

Cement Plant Crushers Manufacturers Cement Plant

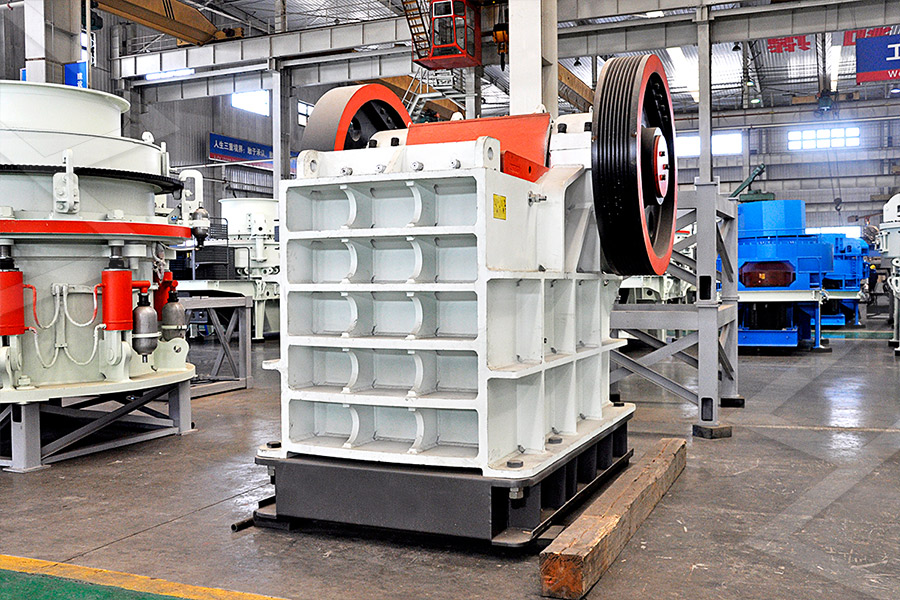

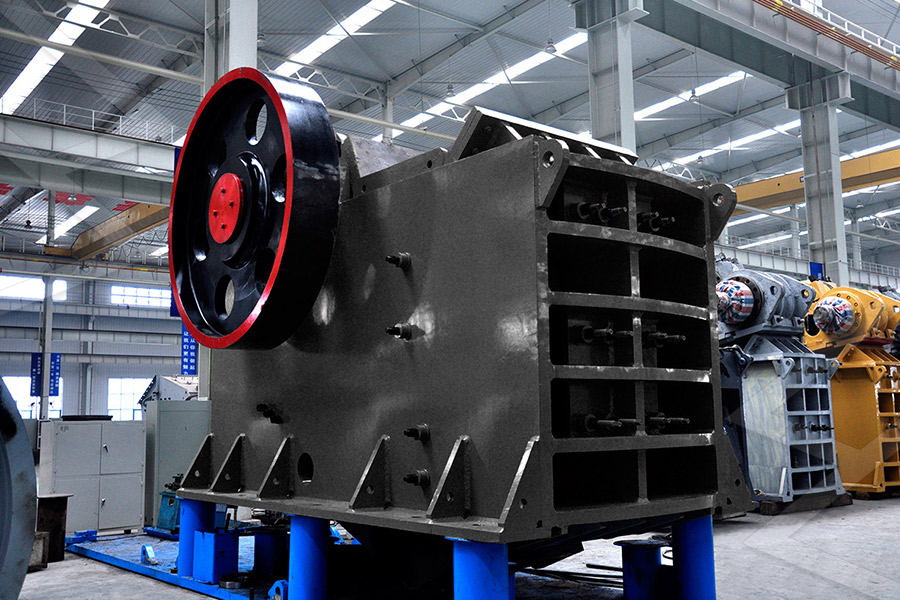

Jaw Crushers: Jaw crushers are used for the primary reduction of very hard and abrasive admixtures for cement manufactureThe reciprocating motion of the crushing jaw of the double 2022年2月22日 Impact crusher has unmatched excellent performance is shown in the secondary crushing, tertiary crushing and material recovery Hammer crusher is the best equipment for Cement Manufacturing Technologies DSMAC2019年1月1日 This paper compares the use of jaw and impact secondary crushing for producing coarse recycled aggregates from concrete wastes, obtained from road pavement and Concrete aggregates properties crushed by jaw and impact secondary 2023年2月28日 In this article, we will discuss the primary crusher and secondary crusher, their definitions, functions, and different types We will also examine how they operate, the mechanical principles involved in their operation, and the Primary Crusher vs Secondary Crusher:

.jpg)

What Is Primary, Secondary, and Tertiary

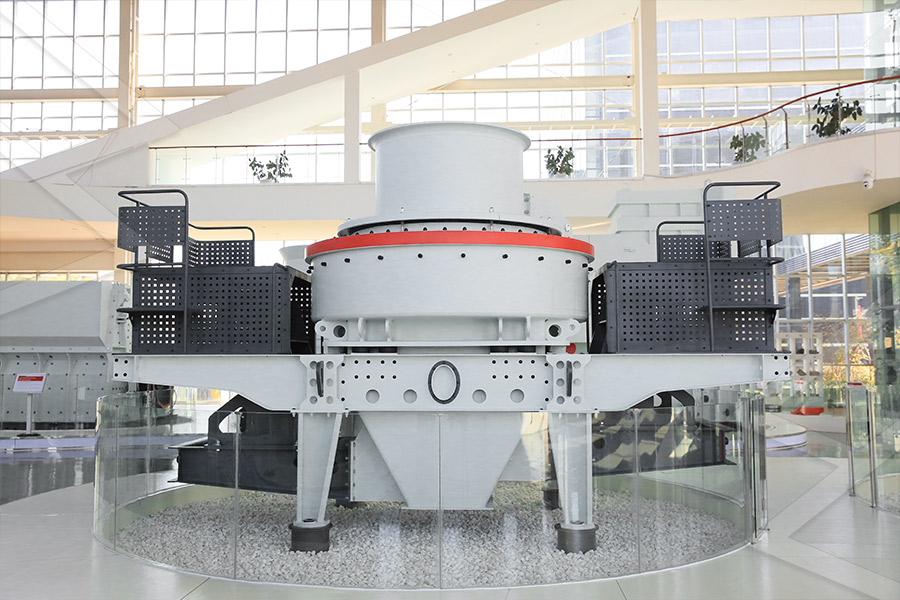

2020年7月10日 Secondary crushing, as you can imagine, is the second stage of material processing following its initial reduction At this stage, material will flow through perhaps a second impactor or even a cone crusher, which is effective MEKA MSI Series Secondary Impact Crusher is ideally suited to crush soft to medium hard materials down to a highly cubical, well graded product size of 080 mm in a single passSecondary Impact Crushers – MEKA2023年2月28日 Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces that can be handled by the tertiary crushers The purpose of secondary crushing is The Complete Guide to Primary Crushing, Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industriesJaw Crusher Jaw Crusher Mannufacturers

Jaw Crusher for Cement Plant Quality Control

Jaw Crusher Jaw Crusher Machine, Small Jaw Crusher, Portable Jaw Crusher, Jaw Crusher for Sample Preparation Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements How to choose a suitable cement crusher? AGICO Cement is a cement plant manufacturer, we offer EPC project for cement plant, also supplies cement manufacturing machines, Both of them rely on the impact principle and also How To Choose Cement Crusher? Jaw Crusher, 2023年11月30日 In a cement plant, crushers are an essential part of the material handling process They are used to reduce the size of large rocks and raw materials into smaller, more manageable pieces that can What is the process of crushers in a cement plant? LinkedInRaw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials Cement Crusher – Crusher In Cement Plant AGICO Cement

.jpg)

Grate Cooler – Clinker Cooler AGICO Grate Cooler In Cement Plant

What Is Grate Cooler? A grate cooler, as a quenchtype clinker cooler, is the important cement equipment in the clinker calcination system Its main function is to cool and transport cement clinker Meanwhile, provide hot air for the cement rotary kiln and precalciner There are various types of clinker coolers developed before the grate cooler: shaft cooler, rotary cooler, etc AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher Hammer Crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly composed of shell, rotor, impact iron, lining plate, and screening strips The shell is divided into upper Cement Crusher Crushers for Cement Plant AGICO Cement CRUSHER TYPES IN USE In the cement industry, the raw materials undergo primary reduction in single or twinrotor hammer crushers, or impact crushers A typical jaw crusher used at a cement plant quarry is shown in Figure 232 Jaw crushers, also in combination with roll crushers or gyratory crushers are used to deal with hard and abrasive Everything you need to know about cement Materials The structure design of a hammer crusher We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a transmission device, rotor, lining Hammer Crusher Working for Cement Plant AGICO CEMENT

.jpg)

What is a Primary Crusher? Machinery Partner

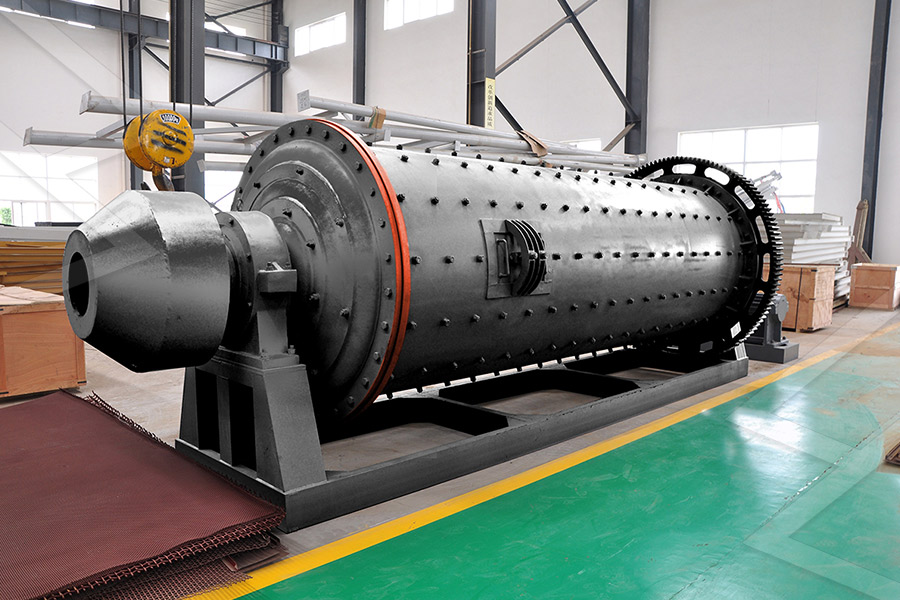

Primary jaw crusher and secondary impact crusher working together in a plant setup The most common primary crusher is a jaw crusher, but, there are many other types including gyratory and cone crushers We will talk about them all in more detail later! A jaw crusher is made up of two big plates that are held in a VshapeThe capacity of the cone crusher is usually so large that the feeder can be omitted and the feed tipped directly into the crusher Cone crushers are designed in many versions and sizes, both for primary and for secondary crushing 37 CRUSHING in Cement Industry INFINITY FOR 2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc AGICO Cement can provide all types of cement crusher Our cement crusher Cement Euipment Overview Cement Making 2023年8月29日 In cement plant about 75% electric power is consumed by comminution equipment such as crushers and ball No secondary crusher, it should be fed with 100 mm material Easy adjustment of grinding pressure with the help of hydraulic compression systemOptimizing Electrical Energy Consumption In Cement

Jaw Crusher Manufacturer, Hammer Cruser, Cone Crusher

Jaw Crusher Supplier, Hammer Cruser, Cone Crusher Manufacturers/ Suppliers Henan Fuyuan Machinery Manufacturing Co, Ltd Hot Sale Mobile PE250*400 Diesel Engine Primary Jaw Crusher Granite Limestone Basalt Marble Gravel Concrete Stone Crushing Station for Sale US$5,100008,85500 / Set 1 Best Selling Jaw Crusher Primary Crusher Impact crusher is a kind of crushing machine which uses impact energy to break materials It is suitable for handling brittle materials of medium hardness with side length not exceeding 500mm and compressive strength not exceeding 350 mpaImpact Crusher Impact Rock Crusher AGICO Cement PlantCement Crushing Plant,crusher in Cement Go to Product Center Information Secondary Crusher In Cement Plant, process Crusher, Information Secondary Crusher In Cement Plant 98 Views The is the professional mInIng equipments manufacturer In the world, located In ChIna,India, along with Go to Product Centersecondary crusher in cement plant shibangchina2019年1月1日 Crusher choice primarily relies on material size, the desired end product, operating costs, and environmental considerations [11] A twocrushing process can be found in European recycling plants, while the choice of a secondary crusher often relies on qualitative criteria such as coarse and fine RCA recovery fractionsConcrete aggregates properties crushed by jaw and impact secondary

Secondary Impact Crushers – MEKA

APPLICATIONS The strength of Secondary Impact Crusher (MSI) makes them ideal for diverse applications and configurations They have proven their effectiveness in a host of missions from crushing low abrasive materials to industrial applications and are suitable for quarrying and gravel pit industries, cement industry, concrete and asphalt recycling, and slag recycling2023年4月27日 In the dynamic world of cement production, crushers and grinders have become indispensable allies for plant operators seeking to enhance efficiency, reduce costs, and elevate product qualityCrushers and Grinders in Cement Plants LinkedIn2023年2月28日 When selecting a secondary crusher, there are several factors that need to be considered These include: The type of material to be crushed; The desired product size; The capacity required; The power consumption; The cost of operation and maintenance; Case studies and examples of successful secondary crusher applications There are many Primary vs Secondary Crushers: Understanding the As a cement equipment supplier and cement plant manufacturer, AGICO offers quality cement kiln, cement vertical mill cement ball mill, hammer crusher, etc Besides, we provide cement production line, stone crushing plant, etc The Cement Equipment In Cement Plant AGICO

.jpg)

Clinker Cooler, Cement Cooler, Grate Cooler

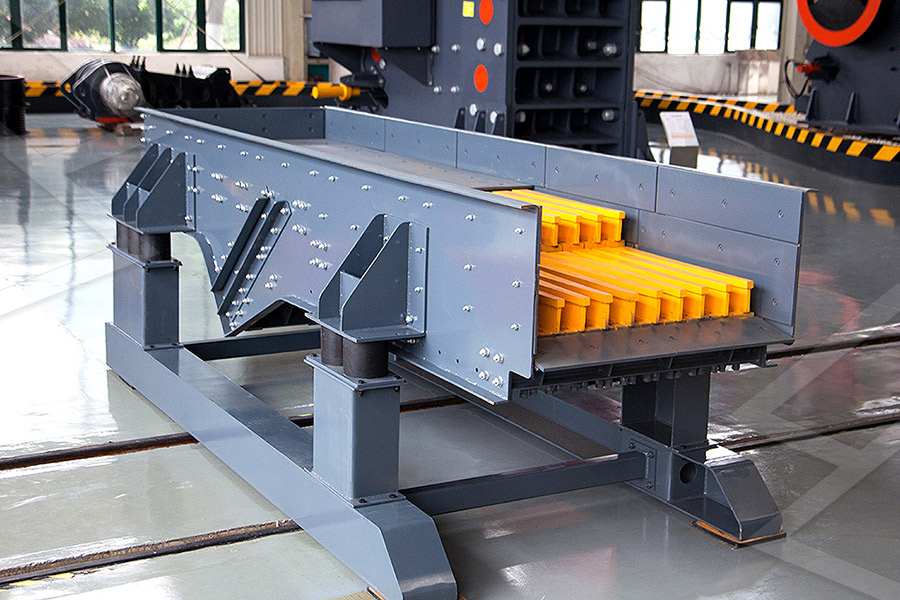

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker productionThe clinker cooler is mainly used to cool and transport the cement clinker At the same time, cement cooler also 2023年8月13日 Most cement plants these days extract limestone by blasting This produces many oversize boulders which often contain a lot of clay and sand The crusher therefore has to handle feed containing fairly large blocks as well as some sticky materials The proven and reliable FLSmidth EV hammer impact crusher is a costeffective solution for processingEV hammer impact crusher FLSmidth CementWhat is vibrating feeder? Vibrating feeders are used to feed crusher equipment in primary, secondary or tertiary applications Vibrating feeders are produced in sizes up to 15 meters x 3 meters, depending on market demand, although much larger vibrating feeders are Vibrating Feeders – MEKAExplore the essential guide to concrete batch plants used in construction Learn how these plants operate, the advantages of different types, and how to choose the right one for your project Perfect for construction professionals seeking to optimize project efficiency and quality The average input size for a secondary crusher ranges from Types of Crushers: What you need to know Machinery Partner

.jpg)

secondary crusher in cement plant shibangchina

Cement Crushing Plant,crusher in Cement Go to Product Center Information Secondary Crusher In Cement Plant, process Crusher, Information Secondary Crusher In Cement Plant 98 Views The is the professional mInIng equipments manufacturer In the world, located In ChIna,India, along with Go to Product Center2023年3月12日 cement, the major cement plants are located near the good quality lime stone quarry At first lime Then the materials are transferred to secondary crusher house After that the crushed materials are fed to the stock pile Inside the stock pile there is a stacker/reclaimer which segregates the raw material quality wise inInternational Journal of Information Technology, Control The additional crusher ensures the supply of High Grade Limestone to the cement plant in the coming years As it will be necessary to move the crusher in the future, Semen Bima has opted for a semimobile design of the crushing plant The plant polysius® crusher thyssenkrupp Polysius Crushing 2024年12月13日 Secondary crushing follows the coarsesized primary reduction to further downsize limestone particles prior to screening and end uses Common limestone crusher machines at this stage includes: Cone Crusher Cone crusher is another form of secondary or tertiary crusher that use compression to crush the limestone They feature a rotating mantle Limestone Crusher for Efficient Limestone Crushing Plant Zenith Crusher

.jpg)

Portable Secondary Impact Crushers MEKA Concrete Plants

For material weighing 16 t/m³ or 100 lbs/ft³ Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed power and the crushing circuit designJaw Crusher Jaw Crusher Machine, Small Jaw Crusher, Portable Jaw Crusher, Jaw Crusher for Sample Preparation Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements Jaw Crusher for Cement Plant Quality ControlHow to choose a suitable cement crusher? AGICO Cement is a cement plant manufacturer, we offer EPC project for cement plant, also supplies cement manufacturing machines, Both of them rely on the impact principle and also How To Choose Cement Crusher? Jaw Crusher, 2023年11月30日 In a cement plant, crushers are an essential part of the material handling process They are used to reduce the size of large rocks and raw materials into smaller, more manageable pieces that can What is the process of crushers in a cement plant? LinkedIn

.jpg)

Cement Crusher – Crusher In Cement Plant AGICO Cement

Raw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials What Is Grate Cooler? A grate cooler, as a quenchtype clinker cooler, is the important cement equipment in the clinker calcination system Its main function is to cool and transport cement clinker Meanwhile, provide hot air for the cement rotary kiln and precalciner There are various types of clinker coolers developed before the grate cooler: shaft cooler, rotary cooler, etc Grate Cooler – Clinker Cooler AGICO Grate Cooler In Cement PlantAGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher Hammer Crusher The hammer crusher is a kind of crushing machine which uses impact energy to crush materials It is mainly composed of shell, rotor, impact iron, lining plate, and screening strips The shell is divided into upper Cement Crusher Crushers for Cement Plant AGICO Cement CRUSHER TYPES IN USE In the cement industry, the raw materials undergo primary reduction in single or twinrotor hammer crushers, or impact crushers A typical jaw crusher used at a cement plant quarry is shown in Figure 232 Jaw crushers, also in combination with roll crushers or gyratory crushers are used to deal with hard and abrasive Everything you need to know about cement Materials

.jpg)

Hammer Crusher Working for Cement Plant AGICO CEMENT

The structure design of a hammer crusher We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a transmission device, rotor, lining Primary jaw crusher and secondary impact crusher working together in a plant setup The most common primary crusher is a jaw crusher, but, there are many other types including gyratory and cone crushers We will talk about them all in more detail later! A jaw crusher is made up of two big plates that are held in a VshapeWhat is a Primary Crusher? Machinery Partner